|

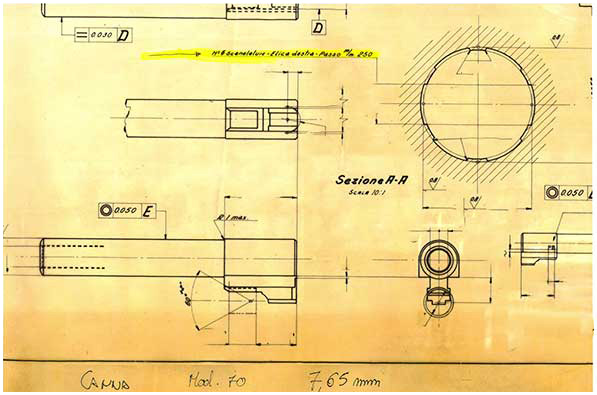

In 1958, a complete redesign of the medium-frame Beretta pistols was put into production. Here ended the Model 924, Model 935, Model 984, and Model 949, replaced by guns that would be known as the "70 Series." Externally, the basic "Beretta look" was retained, but the front of the trigger guard now had a graceful sweep up to the frame. The grips were changed to the type used on the Model 951, meeting at the rear to form the backstrap, and the shape was improved. Other features of the Model 951 were also used on the early versions, including the cross-bolt sear-block safety and the push-button magazine catch. An automatic external slide latch was also added. |

|

|

This safety change also occurred in the other 70-Series pistols, Models 71 through 76. The Model 71 was the 22 Long Rifle version, and in appearance and features it was identical to the Model 70. Like the .32, it has a magazine capacity of eight rounds. The Model 71 was marketed in the U.S. as the "Jaguar." The Model 72 was essentially the same as the Model 71, but was supplied with two interchangeable barrels, the extra one having a length of 150mm (5.9 inches). In the target pistol area, the Model 74 was similar to the Model 73, but the barrel-mounted rear sight was fully adjustable, both vertically and horizontally. The Model 75 was the same as the Model 72, but with the long barrel only. Beretta's first serious .22 target pistol was the Model 76. The frame and slide were similar to these units on the other 70-Series pistols, but an extended and weighted barrel assembly was added. Its upper section extended back over the top of the slide and carried a well-designed and fully-adjustable rear sight. During a brief period in the late 1960s, several of the pistols described were model-numbered in a separate 100-Series designation on the U.S. market. Following enactment of the federal firearms law of 1968, with its strange "importation criteria, a version of the 7.65mm Model 70 was offered with the longer barrel and grip frame of the .22 pistols, and with adjustable sights. It was called the Model 100, and was marked on the right slide flat "P.B. - MOD. 100 - MADE IN ITALY." This pistol was not made in large quantity. |

|

|

The 100-Series designations were applied to several other Beretta pistols of the period. The Model 101 was the Model 71, and the Model 102 was the Model 76, also known as the "New Sable." In the same group was the Model 951, which was very briefly called the Model From "Beretta Pistols: The Ultimate Guide" by J.B. Wood - (c) StoegerBooks. |

|

|

| Features | ||

|

1) INCREASED ACCURACY OF FIRE - The barrel guide, fitting the barrel into the receiver, has been lengthened almost equalling that of the Beretta 01ympic target pistol. This definitely increases the accuracy of fire at both short and long ranges. 3) CRISP TRIGGER PULL - An improved sear release mechanism, utilizing new steel alloys, ensures a crisper and smoother trigger pull for more precise shooting. 4) SPEEDY MAGAZINE RELEASE - New Beretta push button magazine release facilitates high speed insertion and extraction of the magazine. SUPERIOR POINTABILITY - The slanted pistol grip provides easier aiming. Newly designed stocks are both easier and faster to grip. Cartridges now enter the chamber with reduced loading angi e. EXCLUSIVE SIMPLIFIED TAKEDOWN (See photographs of field strip sequences). |

|

|

2) HIGH SPEED

THUMB SAFETY LEVER- At last it has been possible to design a completely

satisfactory safety lever, blocking both hammer and sear when

the pistol is at full cock. The safety may be applied (UP) or released (DOWN) with lightening speed pushing the lever up or down with the side of the thumb. |

|

| Disassembly | ||

|

1 First

remove magazine, then draw the slide back for a look into the

chamber and check that it is empty. (Cock hammer first to facilitate backward movement of slide) To remove magazine, keep push button magazine release pressed down until the magazine is fully out. Reassemble in reverse order. |

|

|

2 Hold pistol in left hand (tap muzzle against a wooden surface to loosen barrel). Push slide back with right hand till notch on the lower edge of the right side of the slide is opposite the slide lock. With left thumb rotate matted button of slide lock counterclockwise. (Fig. 2). | |

|

3 The slide is thus released and permitted to come forward, on the front. | |

|

4

To remove barrel, release recoil spring guide with its spring, pushing

it slightly forward to disengage from notch in the slide. (Be careful

since the recoil spring is tightened). Proceed as shown in figure

4.

Reassemble in reverse order |

|

Spare Parts |

||

|

||

|

20. hammer spring strut nut |